Bureau Veritas metalworking fluid analysis programs help our customers maintain high standards of product quality, improve equipment reliability and extend tool life.

In both metal-removing and metal-forming applications, where high-speed, high-production and high-friction operations make lubricity and cooling critical, Bureau Veritas designs metalworking fluid testing programs that:

- Monitor contaminants to inhibit corrosion and prevent microbial growth

- Measure pH to maintain metal solubility and fluid stability

- Provide system flushing and filtration procedures to improve new fluid performance

- Help prevent serious health risks and environmental issues that poorly maintained metalworking fluids can create

Testing concentration and pH on a daily basis – or at least three times a week – monitors corrosion, metal solubility and emulsion stability. Acids, biocides and dirt can be monitored on a weekly basis but should results change, daily testing should be done until the cause has been identified and levels return to normal.

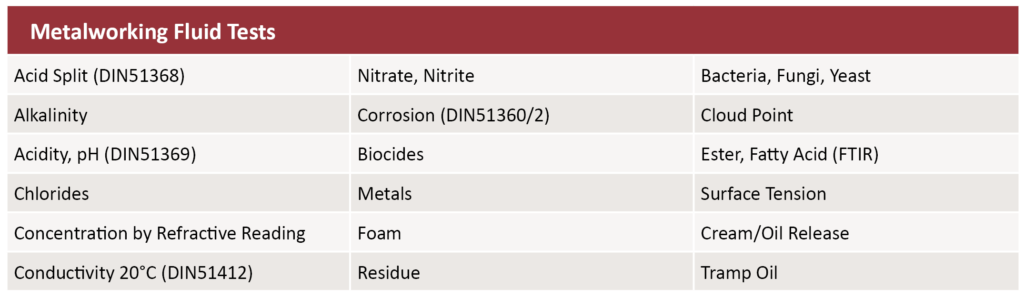

Metalworking Fluids We Test

Testing and sampling frequency are dependent upon the application, the machining process – rolling, cutting or grinding – and the metal alloy being machined. With Bureau Veritas, you can be confident your metalworking fluid test slate includes the proper testing at the appropriate sampling frequencies to identify the onset of potential problems.

Straight Oils

The mineral-based straight oils used in medium to heavy duty applications provide more lubrication than cooling. While they can contain additive packages for enhanced performance, straight oils are the only metalworking fluid not diluted with water. As a result, they don’t experience the same foaming, fungus and bacterial problems as water-based fluids and therefore require less frequent testing.

Water-Dilutable Fluids

The emulsifiable oils, synthetics and semi-synthetics used in medium to heavy duty finishing and grinding applications that require lubricity can be diluted with water to increase their cooling capabilities. Therefore, they should be frequently monitored for foam, corrosion, fungus and bacterial growth.